Emerging 3D Printing in Strategic Energy Budgeting

by Verner Mayer

by Verner Mayer

Explore how 3D printing is transforming energy efficiency and budgeting for businesses. This article covers practical strategies, real-world case studies, and trends that help optimize energy use and reduce costs in sustainable ways.

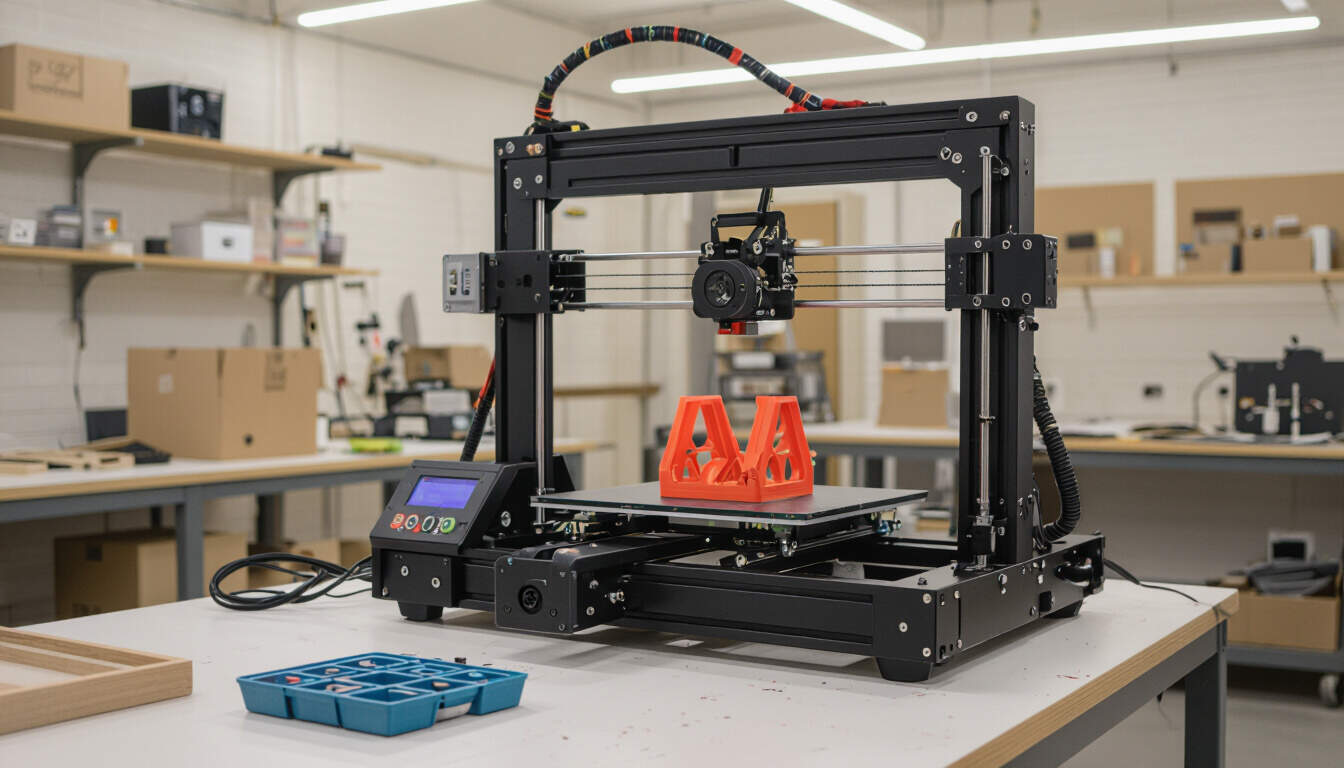

3D printing is making waves in various industries, particularly in how organizations approach energy management. This technology offers innovative ways to optimize resources and cut down on waste, directly impacting energy efficiency. For business professionals and energy managers, integrating 3D printing into operations can lead to smarter financial decisions.

One key area is the production of custom energy components. Businesses can create parts on demand, reducing the need for large inventories. This approach minimizes material waste and lowers overall energy consumption during manufacturing processes. By focusing on precise designs, companies achieve better performance from their equipment.

In practice, several strategies stand out. First, using 3D printing for prototyping allows for rapid testing of energy-saving devices. Engineers can iterate designs quickly, ensuring that final products are as efficient as possible. This method not only speeds up development but also helps in identifying cost-effective solutions early.

Another strategy involves on-site production of parts for renewable energy systems. For instance, solar panel components or wind turbine parts can be printed locally. This reduces transportation emissions and associated costs, making strategic energy budgeting more straightforward. Organizations save on logistics while maintaining high standards of sustainability.

Case studies illustrate these benefits clearly. A manufacturing firm in Europe adopted 3D printing to produce custom fittings for their heating systems. By doing so, they reduced energy loss by 15% through better insulation. The initial investment was recovered within a year due to lower operational expenses. This example shows how targeted applications can yield measurable results.

Similarly, a utility company in North America used 3D printing to fabricate lightweight components for their grid infrastructure. This led to a 10% reduction in material use and improved the overall reliability of their systems. Energy managers reported easier budget allocations because of the predictable savings from reduced maintenance needs.

Emerging trends are pushing the boundaries further. Advances in materials science mean that 3D printers can now work with sustainable substances like recycled plastics or bio-based resins. These materials enhance the environmental profile of printed items, aligning with broader sustainability goals. As a result, businesses can plan their energy budgets with a focus on long-term ecological benefits.

In the context of energy efficiency, additive manufacturing techniques are evolving to include multi-material printing. This allows for the creation of complex structures that integrate multiple functions, such as sensors within energy devices. Such innovations help in monitoring and optimizing energy use in real time, providing data for informed budgeting.

For sustainability enthusiasts, the role of 3D printing in circular economies is particularly promising. Items can be designed for easy disassembly and recycling, extending their lifecycle and reducing waste. This circular approach supports strategic planning by minimizing the environmental footprint and associated costs.

To implement these strategies effectively, organizations should start with an assessment of their current energy usage. Identifying areas where 3D printing can make an impact is crucial. For example, creating a list of high-consumption processes and evaluating how customization could improve them.

- Assess current operations: Review energy-intensive activities and pinpoint opportunities for 3D printing.

- Invest in training: Ensure staff are skilled in using the technology to maximize efficiency gains.

- Monitor outcomes: Track metrics like energy savings and cost reductions to refine strategies.

These steps form a foundation for integrating 3D printing into energy management plans. Over time, the data gathered can inform more precise budgeting, turning initial efforts into ongoing improvements.

Looking ahead, the intersection of 3D printing and energy efficiency will likely expand. New regulations on carbon emissions may accelerate adoption, as businesses seek compliant and cost-effective solutions. By staying informed on these developments, energy managers can position their organizations for success.

In summary, 3D printing represents a forward-thinking tool for strategic energy budgeting. Through practical applications and emerging innovations, it empowers businesses to achieve greater efficiency and sustainability. As more case studies emerge, the potential for widespread impact becomes even clearer.